BECK HIGHLIGHTS OF THE DACH + HOLZ 2024 TRADE show

Discover now the innovations from fastening pioneer BECK for the roofing and timber construction industry at DACH + HOLZ International 2024 in Stuttgart

As a pioneer in the development of new ideas and innovative fastening systems, e.g. for timber construction, we set standards. It is often the small things that make a big difference. Discover now the latest innovations from BECK, presented at Dach und Holz International 2024.

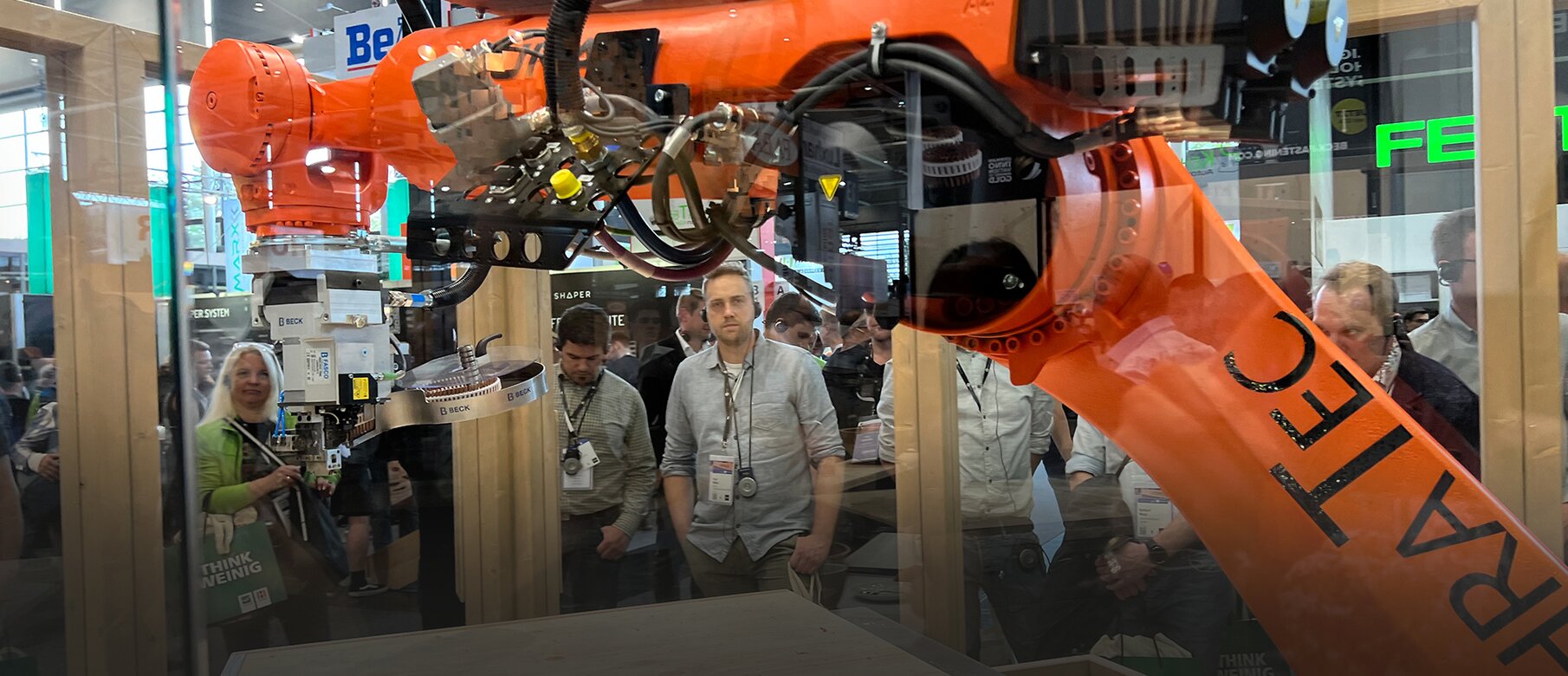

SERIAL CONSTRUCTION WITH WOOD & LIGNOLOC® WOODEN NAILS

Build faster and more sustainably: With its flexible, digital robot platform, BECK, together with its cooperation partner Kehratec, offers a perfect solution for the partially or fully automated implementation of ecological timber construction projects. The robot-assisted system can be used to easily prefabricate glue- and metal-free wall and ceiling elements in series. The live demonstrations at the trade show stand will show how the individual board layers are fastened by the robot with the LIGNOLOC® wooden nails to create a wall element. The nailing is done with a FASCO® nailing head, BECK's tool brand. The automation solution will be presented at the trade show stand with an original KUKA robot and a real wall cut-out.

As individual as your projects require

The system can, of course, be programmed and customized according to the desired specifications. It is therefore possible to produce LCLT (CLT manufactured with LIGNOLOC® wooden nails), board stacked ceilings and timber stud walls in one and the same machine. All adjustments and changes can be carried out conveniently via remote maintenance, without the machine operator needing any knowledge of robotics.

Interested? Contact us now and request additional information.

NEWLY DEVELOPED: THE SPECIAL SCRAIL® ANCHOR AND SCRAIL® CHIPBOARD NAIL SCREW fasteners

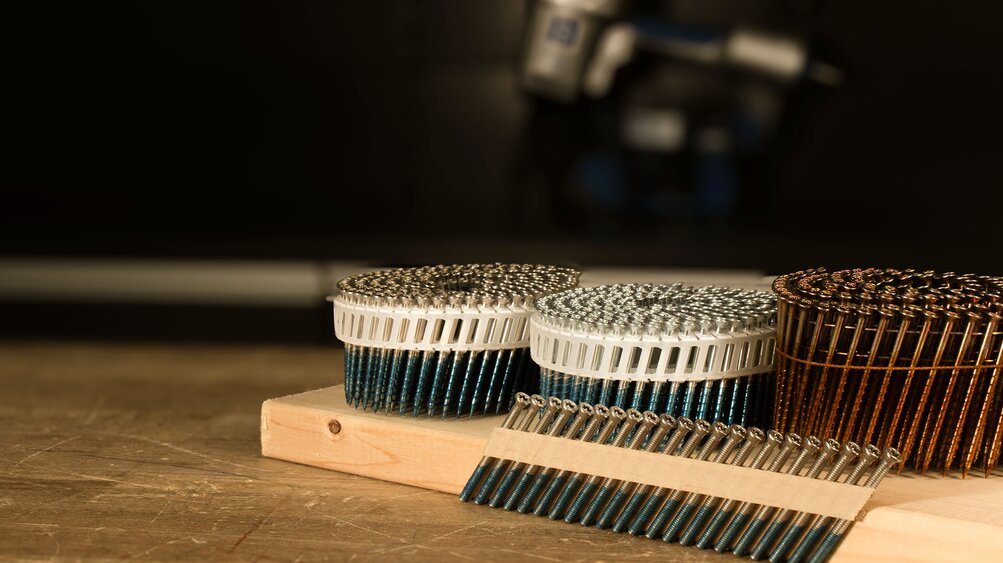

The innovative SCRAIL® product group has grown with the addition of the special SCRAIL® ANCHOR and SCRAIL® CHIPBOARD nail screw fasteners.

SCRAIL® CHIPBOARD

The new SCRAIL® CHIPBOARD nail screw fasteners impress with their rolled-out needle point, which ensures optimum driving and retightening behavior. Their easy readjustment makes them the perfect choice for temporary applications in very soft wood or wood-based materials, e.g. in crate construction, but also for fastening chipboard. The SCRAIL® CHIPBOARD is also ideal for outdoor projects. In its stainless-steel version, optionally with or without black oxidation for a perfect visual blend with weathered wooden boards, it demonstrates its versatility. Another plus: the thread geometry even allows curved or warped wooden boards to be tightened. The SCRAIL® CHIPBOARD nail screw fasteners are available in lengths from 50 to 90 mm and can be easily processed with the FASCO® F50 CN15W-PS65 SCR or the F60 CN15W-PS90 SCR in the SCRAIL® Edition, thus offering maximum flexibility for a wide variety of projects.

Focus on the newly developed SCRAIL® CHIPBOARD and SCRAIL® ANCHOR nail screw fasteners - for high speed, maximum holding force and full flexibility.

SCRAIL® ANCHOR

Incomparably fast and unparalleled flexibility - that describes our new SCRAIL® ANKER nail screw fasteners. Specially developed for the efficient fastening of timber connectors in structural timber construction, they are the perfect alternative to conventional anchor nails. Compared to conventional anchor nails, our collated SCRAIL® ANCHOR nail screw fasteners offer an impressive 8 times faster driving speed. In contrast to anchor nails, SCRAIL® ANCHOR can also be easily readjusted or completely removed. This means less effort, especially when dismantling carports, play towers and similar structures. And for outdoor use, our SCRAIL® ANCHOR nail screw fasteners are of course also available in stainless-steel quality.

Discover the unbeatable combination of speed and flexibility now! To the products

Fast, flexible, strong: SCRAIL® ANCHOR nail screw fasteners for the efficient connection of timber connectors in structural timber construction

Downloads

Get all the information about our trade show innovations now! Download our catalog, brochures, and technical handouts to get a detailed insight into our cutting-edge innovations.