BECK GOES BLACK

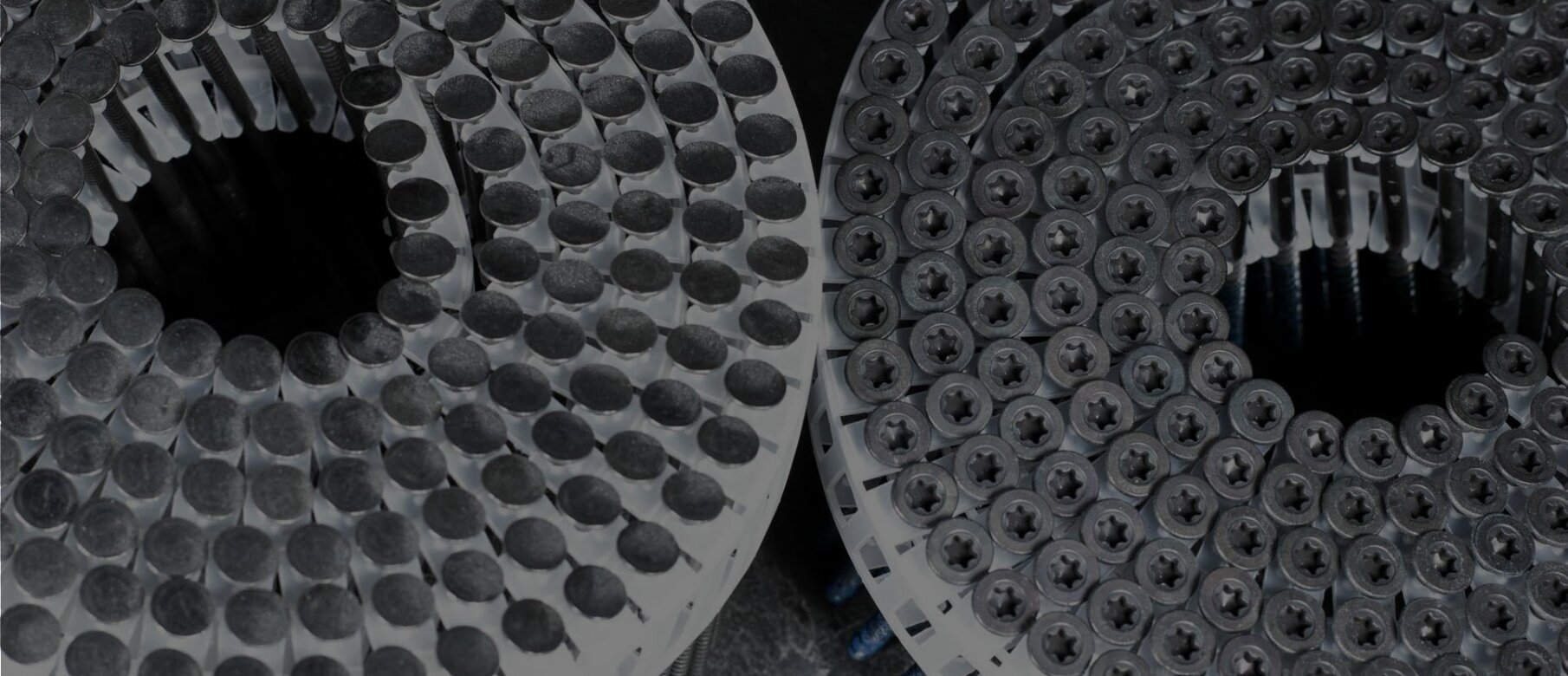

Black oxidated nails & SCRAIL® nail screws perfect for installation of darkening wood facades & decks.

Our new black oxidated stainless steel coil nails and SCRAIL® nail screw fasteners harmonize with naturally weathered (grey) wood - both on façades and softwood decking. Both types are available in different sizes, with or without Diamond Coating for maximum grip. Black oxidation is a new surface treatment for all SCRAIL® nail screw fasteners and stainless steel nails made by BECK. Nickel atoms on the surface of the stainless steel are chemically oxidated at a temperature of 266 °F, which turns the surface black and ensures several advantages.

ADVANTAGES

-

Consistent wood look without distracting reflections

Black oxidated SCRAIL® nail screw fasteners and nails are ideal for wooden façades and decking boards, which darken considerably. Reflections as with normal stainless-steel products are avoided. -

Good adhesion of the oxide layer

The layer is resistant to bending and abrasion for optimum material protection.

-

Long-lasting protection

Surface is wipe resistant and resistant to alkaline solutions. -

True to size coating

With less than 1 μm coating thickness, BECK's black oxidated nails and SCRAIL® nail screw fasteners remain true to size.

FAQ

Black oxidated stainless nails combine both aesthetic and technical aspects, depending on specific requirements and intended use. Here are some considerations:

Aesthetic aspects

Black oxidation gives nails an appealing dark or even black color, which is often desired for stylistic reasons. This can contribute to a particular design or style and is popular in projects where appearance is important. The black color also gives the nails a unique look that stands out from the usual metallic finishes. In many cases, this even has practical benefits, such as reducing light reflections and glare.

Technical aspects

The oxide coating created by black oxidation can also influence the friction properties. This could be advantageous in some applications, e.g. when it comes to the penetration depth or the longevity of nails.

Pressure and friction are generated when nails are shot. This could wear down the nails on painted surfaces and damage the paint finish, especially if the surface is subjected to hard contact or impact forces. The high quality oxidation treatment on stainless steel nails results in the oxide layer on the nails being perfectly preserved and the protective layer being durable and resistant to abrasion.

Black oxidated stainless steel nails are treated with a dark or black oxide layer on the surface. The corrosion protection of black oxidated stainless steel nails is usually the same as the corrosion protection of non-oxidated stainless-steel nails.

As a rule, black oxidation can be achieved with different types of stainless steel, but the exact results may vary depending on the type of stainless steel. The possibility of black oxidation of stainless steel depends on the exact composition of the stainless steel. A2 and A4 are designations for different types of stainless steels defined in the DIN EN ISO 3506 standard.

All information, compactly summarized, can be downloaded here as a PDF.